Vessel cargo hold area is inevitably exposed to seawater during navigation. Even little amount of water leaking into vessel cargo hold area would cause severe damage to sensitive goods such as steel products and cereals.

For this reason, hatch cover weather tightness testing becomes a critical factor to evaluate ship condition, by P&l Club, cargo interests and shipowner. To ensure vessel’s seaworthiness and cargoworthiness, hatch cover weather tightness test has gradually become a common detection approach.

SAG ultrasonic hatch cover leak detector utilizes ultrasonic technology to quickly and effectively detect and assess the seal integrity of hatch covers and other enclosed spaces. SAG Ultrasonic Leak Detector is currently the only one having been approved by Classification Society for the purpose of testing hatches weather tightness in China. lt features high cost performance, high reliability and economical maintenance cost, and can meet the needs of domestic and foreign markets.

As a fast and convenient detection method, ultrasonic detection is also a reliable and environmentally friendly nondestructive testing approach.

By an easy handling way,minimize the time taken to identify the potential leakage.

Enable quick decision for proper repair method by evaluating leakage extent according to the decibel reading.

Ultrasonic Technology Advantages

| Traditional Host Testing | Ultrasonic Leak Testing |

| Oil or pollutant pollution on the deck area. | Environmental-friendly |

| Difficult to identify exact leakage areas | Accurate indicating hatch covers’ weather tightness location and extent of leakage points. |

| Unable to ensure water pressure stable at all test points | Ultrasonic signals uniform and stable to cover all corners of a hatch cover |

Ultrasonic detection has been recognized by various classification societies. DNV-GL, and Lloyd’s Register of Shipping had issued supplier approval certificates to some detection organizations. Detecting personnel should meet the criteria stipulated in IACS Z17 and requirements by different classification societies. Besides, the detecting instrument should be calibrated timely and the detecting personnel should receive training and obtain relevant qualifications organized by the detecting instrument manufacturers.

How to use ultrasonic leak detectors?

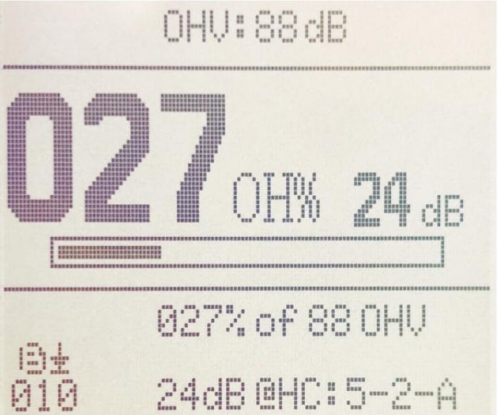

The ultrasonic transmitter is placed in the hold while the handheld receiver on the weather deck is moved around the joint areas of closed openings. The strength of the received signal, measured in decibels, indicates whether the joint is weather tight or not. It is accurate, convenient and harmless.

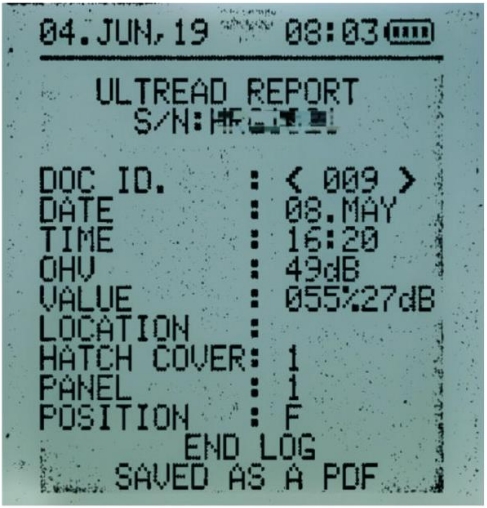

A 2.16 inch screen, flat interactive design, all information displayed, including dB and OHV values.

Leakage record can be directly checked on the receiver.

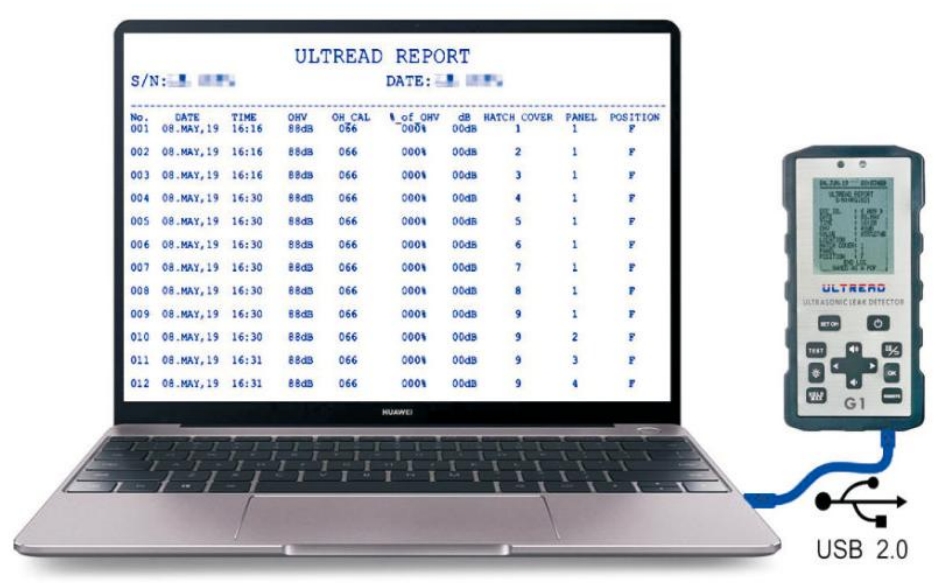

Connecting the receiver to a computer via USB, a report can be exported in PDF format.

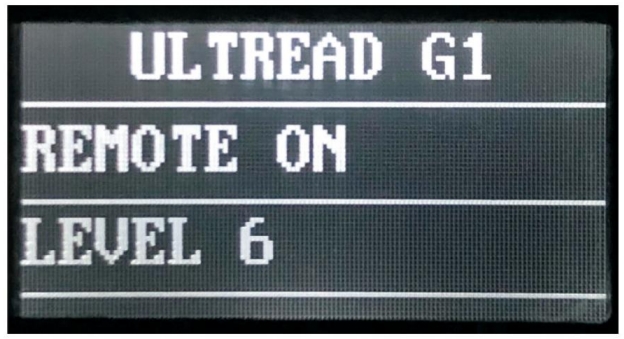

Equipped with a 0.96-inch OLED screen, making remote control status, power level and operational status plain as daylight.

Equipped with a 6-grade power knob, providing 83-115dB sound pressure level signals, meeting the detection requirements for a range between 0.5m and 20m.

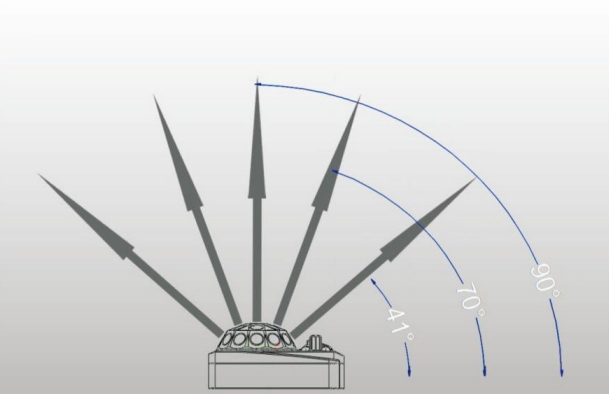

A Three-layers signal based multi-angle transmitting probe, applicable to cargo space with different depth, and capable of reducing signal refraction losses and ensuring uniformity and stability of signals.

Either a fold type hydraulic hatch cover or a sliding type hatch cover, it is composed of block-shaped hatch cover panels. In line with a habitual order from forward to aft and from port to starboard, detected positions are labeled as follows:

Leakage area between 2nd and 3rd hatchcover panels in No.5 cargo hold are marked as HC:5-2-AFT

In a log menu,operational procedures:

(1)Select a serial number of the first leakage record;

(2)Select a serial number ofthe last leakage record;

(3)Press the button OK to create a PDF file

Ultrasonic hatch cover leak detector kit package

●ULTRASONIC receiver

●ULTRASONIC transmitter

●Flexible Sensor(10mm)

●Telescopic extension with sensor cable

●Headphones

●2 16430 batteries for receiver

●6 AA batteries for transmitter

●Micro USB cable

●Operation manual

ULTRASONIC Receiver Specifications

| Display | 128×128 pixels LCD(2.16 inch) |

| Keyboard | 12 function keys |

| Measuring range | 0-92dB(reference 0dB=1μV) |

| Measuring bandwidth | 38 KHz to 42 KHz |

| Operation temperature range | -10 to 50℃ |

| IP rating | IP66 |

| Housing material | PC+ABS |

| Housing dimension | 128.8mm * 64.5mm * 31.2mm |

| Weight | 230g |

| Power supply | 2 16340 batteries (6-8 hours) |

| System storage capacity | 999 sets of data |

| PDF displays records per page | 30 records per page |

| Calibration period | 1 year |

| Warranty period | 3 years |

ULTRASONIC Transmitter Specifications

| Housing dimension | 145mm*125.5mm*72.5mm |

| Weight | 500g(with 6 AA batteries) |

| Transmitter frequency | 39.6KHz-41.4KHz |

| Remote range | 50m |

| Power supply | 6 AA batteries |

| Operation temperature range | -10 to 50℃ |

| IP rating | IP30 |

| Housing material | PC+ABS |

Transmitted Sound Pressure Level at 1m, Ref. 0dB=0.0002 μbar and battery lifespan

| Level 1 | 83 dB SPL | 15h |

| Level 2 | 86 dB SPL | 14h |

| Level 3 | 92 dB SPL | 13h |

| Level 4 | 98 dB SPL | 8h |

| Level 5 | 109 dB SPL | 6.5h |

| Level 6 | 115 dB SPL | 5h |

Flexible Sensor Specifications

| Sensor type | Airborne removable resonance sensor(ф 10mm) |

| Resonant Frequency | 40.0±1.0KHZ |

| Bandwidth | 2.5KHz |

| Sensitivity | -70dB min(at 40.0KHz 0dB=1 volt/ μ V) |

| Length | 20cm |

| Weight | 56g |

| Operation temperature range | -10 to 50℃ |

| Extension tube | Extended length 87cm Collapsed length 19cm |