Liquefied gas tanks are widely used for storage and transportation in industrial, residential, and agricultural applications. Accurate and timely monitoring of the liquid level in these tanks is crucial for safety and efficiency. It prevents overfilling, which can lead to excessive pressure, and underfilling, which can disrupt normal usage. Additionally, monitoring helps detect leaks, blockages, and other anomalies that could lead to accidents.

Liquid Level Detection for Liquified Gas

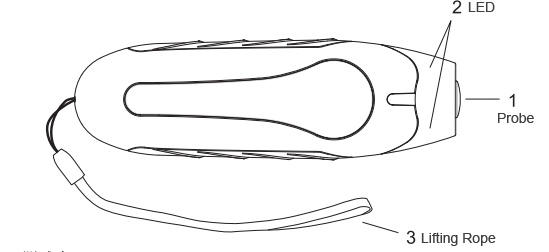

This device is a portable liquid level tester,which can be used to determine whether there is liquefied gas(propane/butane-LPG)present at the height of the test point within the gas cylinder,and it can also be used to measure the height of the liquefied gas liquid level.The instrument is suitable for steel or aluminum cylindrical liquefied gas cylinders with a diameter of 200-350mm.

Size: 146*46*30mm/Weight: About 99g

Power: Battery 9V 6F22

Multiple tests are required to determine the liquid level of the liquefied gas. It is recommended to start measuring from a lower position on the gas cylinder.

Hold the instrument horizontally to ensure that it is perpendicular to the surface of the gas cylinder being tested. Press the test head against the desired test position on the gas cylinder. The instrument will emit a”beep” sound, indicating good contact between the instrument and the gas cylinder.

During the test, the two status indicator LEDs will flash simultaneously. When the instrument emits a second”beep” the test is complete. The two status indicator LEDs will stop flashing and turn off, and then immediately light up to indicate the test result:

- Both status indicator LEDs turn green: This indicates that liquid is present at the test point height inside the cylinder.

- Both status indicator LEDs turn red: This indicates that no liquid is present at the test point height inside the cylinder, or that the test result is inaccurate.

After this measurement is completed, continue to perform several more tests at different heights on the gas cylinder, moving upwards, until the liquid level inside the cylinder is finally determined.

Note: Do not rub or drag the test head on the gas cylinder to avoid damaging the test head.

Approximately 15 seconds after the test is completed, the status indicator LEDs will automatically turn off.

Note:

- The maximum loading capacity of a liquefied gas cylinder is usually 80%of its volume.The liquid level height of liquefied gas will vary with the composition of the liquefied gas mixture(the proportion of propane and butane)and temperature.

- This instrument is not suitable for testing plastic liquefied gas cylinders,gasoline tanks,or butane gas cylinders used for camping.

- To ensure accurate test results,wipe the test head of the instrument with a damp cloth before each use.Do not use cleaning agents.

- A dirty test head can cause inaccurate test results.Liquefied gas cylinders can easily carry dust particles,which can adversely affect the test.Therefore,ensure that the test position on the liquefied gas cylinder is clean before testing.

- Under normal circumstances,testing dirty or rusted liquefied gas cylinders can be difficult.The following conditions may prevent the instrument from conducting tests:

a.Rust on the inner or outer surface of the liquefied gas cylinder.

b.A thick coating(such as paint)on the outer surface of the liquefied gas cylinder.

c.Ice or other condensation covering the outer surface of the liquefied gas cylinder.

d.Dents or severe scratches on the outer surface of the liquefied gas cylinder. - When testing,to ensure accurate results,conduct tests at different heights on the liquefied gas cylinder to verify the accuracy of the test results.